Clean irrigation for 100 hectares of soft fruit

Added on 07 December 2020

Iron oxidizing bacteria

The irrigation water, taken out of the bore holes, is drawn into 50 m3 holding tanks, from where it flows into the main irrigation manifold. The grower reported recurring outbreaks of a slimy white substance within the irrigation lines, holding tanks and irrigation system, which was substantially blocking drippers and resulting in non-uniform irrigation. In addition, the grower also reported iron deficiency in the crops, despite the use of iron fertilizers.

East Seaton asked HPNow for help in combating the negative impact this had on irrigation uniformity, system maintenance costs, crop yield and plant health. Analysis performed by HPNow showed high levels of iron within the white substance, which meant the substance was absorbing iron meant for the plants and explains the observed iron deficiency. Further consultation with plant pathogen experts pointed to iron oxidizing bacteria as the cause of the white substance.

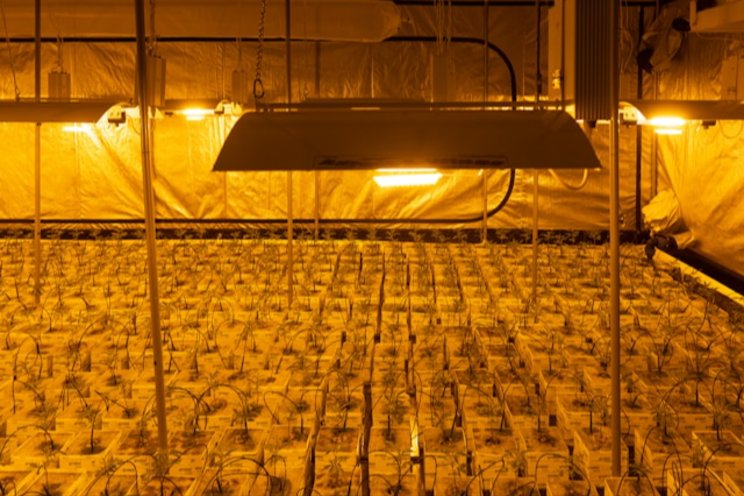

Iron in the fertilizer feeds bacteria growing in the irrigation lines (white slime in the pictures), clogging drippers and depleting the crop from iron nutrients.

After application of Peroxide UltrapureTM the white substance was removed, the drippers were flowing again and the crop's iron deficiency was corrected.

Clean irrigation, healthier crop

HPNow's recommendation was to pursue a combination of periodic shock treatments in the main lines combined with continuous dosage in the laterals throughout all irrigation cycles. HPNow distributor Penny UK installed two HPGen A2000 Peroxide UltraPureTM systems at the farm to control the white substance in the water, leading to positive results within weeks.

Using HPGen Peroxide UltraPureTM proved highly effective for Allen Innes, East Seaton Farm Manager, who reported the white substance was nearly eliminated within a few weeks. "HPGen has been the ideal solution for us, and we are now looking forward to a clean irrigation system and a healthier crop", he comments.

About HPNow

HPNow addresses growing global challenges in clean water and sanitation through its range of on-site, autonomous, safe and sustainable hydrogen peroxide generation solutions. Headquartered in Copenhagen, and with representation across Europe, the Americas and Asia, they address their clients' water treatment needs in market segments ranging from agriculture and aquaculture, to industrial and drinking water treatment. HPNow is a technology and market leader in on-site generation of hydrogen peroxide, and is continuously striving to further advance its technology and products in order to meet growing market needs and rising global demand.

Stay in the loop by following HPNow on LinkedIn and Facebook.

Source: Goedemorgen

More news