Fertiliser made from recycled battery dust

Added on 26 May 2020

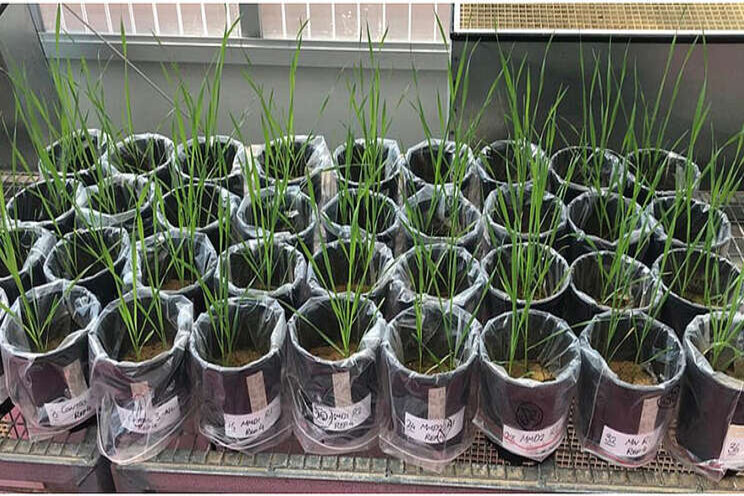

Initial 'pot trials' in controlled greenhouse conditions by Lithium Australia's (ASX:LIT) recycling division, Envirostream Australia, indicated that the "product did have potential".The company concluded that while uptake of zinc and manganese from the mixed metal dust (MMD) was observed "it was slower in comparison to that of fertiliser-grade sulphate products over the compressed duration of the glasshouse pot trial"."That said, the results were encouraging enough for the company to commit to the next stage of assessment," Lithium Australia says.

A bigger field trial site has been selected in the Wheatbelt region to assess the yield performance of the MMD in comparison to commercial fertiliser products.

The Wheatbelt produces about 14 million tonnes of grain each year and is a major contributor to Australia's export economy.

Lithium Australia says soils in the selected area have a 'low pH' and are deficient in zinc, manganese and phosphate - making them an ideal testing ground for Environstream's battery dust.Blending of the manganese/zinc supplement with major-element fertilisers has begun in preparation for wheat seeding, which is anticipated in the next two weeks.Envirostream also plans to conduct field trials in jurisdictions outside Australia.Lithium Australia says this is an opportunity to reduce the carbon footprint of the battery industry and landfill contamination while improving global food production. Win-win."Australia sells around 6,000 tonnes of alkaline batteries a year," Lithium Australia says."In 2019, the nation's Battery Stewardship Council ('BSC') estimated that, at the end of their useful life, 97 per cent of those batteries were disposed of in municipal waste streams and reported to landfill."This is an idea that has already gained traction globally.In March, Finnish company Tracegrow signed a deal with Aussie company ReNutrients to distribute its battery fertiliser in Australia and New Zealand.ZM-Grow, also produced by extracting and purifying the zinc and manganese content of recycled alkaline batteries, has even beat market-leading products in some experiments, it says.

The crops from ZM-Grow treated (left) and untreated (right) patches for comparison.

Ontario based battery recycler RMC Technology claims it can recover 100 per cent of the zinc, manganese and potassium from alkaline batteries, to be used as a premium micro-nutrient to grow corn.The use of RMC micro-nutrients increases corn yields by 20 bushels per acre, it says.

Source and Photo Courtesy of Stockhead

Source: Stockhead

More news