Hydroponic strawberry urban farming

Added on 19 October 2021

When operating outdoors, strawberry farms use raised beds/rows covered with a plastic film. Such plastic material is supposed to act as mulch retaining soil moisture and inhibiting weed growth. It also prevents the fruit from being in contact with the soil or the irrigation system.

In an open field, strawberries are drip-irrigated and fertigated (nutrients are diluted in water and plants receive such liquid fertilizer through the drip tape). Outdoor strawberry farms are seasonal and require challenging harvesting logistics.

On the other hand, a hydroponic strawberry farm inside a climate-controlled greenhouse can operate year-round with the help of artificial lights. However, conventional hydroponic strawberry farms are very expensive to run in extreme climates from an energy cost standpoint.

In a conventional hydroponic strawberry farm, when operating in extreme heat conditions, it is difficult to bring the temperature of a greenhouse below 20-25 °C. This is why even a fully climate-controlled greenhouse in a desert or in a tropical climate, strawberry farming can only be done seasonally and crop yields end up being average.

On the other hand, hydroponic strawberry farms in greenhouses located in cold climate areas are very demanding in terms of energy (artificial lights and heating). However, when well-conceived, such strawberry farms can produce large number of strawberries with extended seasons in comparison to conventional soil farming.

Whether located outdoors or in a greenhouse, one of the big challenges in strawberry farming resides in the harvesting of the fruits.

Strawberries are non-climacteric fruit. They do not keep on ripening after harvest.

Climacteric fruits such as apples, pears, bananas, avocados, kiwis, papayas, and tomatoes, keep on ripening after harvest since these fruits produce and release ethylene gas.

However, non-climacteric fruits such as blackberries, citrus, cherries, cucumbers, peppers, pineapples, raspberries, and strawberries, stop ripening after harvest.

One of the biggest problems with strawberry farming is that the fruit is oftentimes harvested too early. Strawberries are fragile and have a short shelf life. Due to the timing involved in harvesting, packing, distributing and retailing, strawberry farmers do harvest too early to ensure that the fruit is not rotten when it ends being purchased by the customer.

When harvesting strawberries too early, they end up being hard and crunchy in texture and sour in taste. Considering that strawberries stop ripening after harvest, whatever fruit is being picked is basically what the customer experiences in terms of quality a few days later.

Even worse than unripe fruits, many strawberries today are being sold with the top part being white (under the stem). The white part under the stem is referred to 'white elbows' in the world of strawberry farming. Such white elbows are usually the result of temperature fluctuations and/or poor nutrients. The white part never ripens and consumers should not purchase strawberries featuring white elbows.

Whether produced in a hydroponic strawberry farm operating inside a greenhouse, or whether talking about a strawberry farm in open field outdoors, such farms are usually located in rural areas away from cities. This is why strawberry farmers are usually harvesting strawberries too early to circumvent the time constraints of transportation and distribution.

Theoretically, in order to offer ripe strawberries to the market, the fruits need to be grown in an urban context and delivered straight from the farm to the retailer and/or consumer.

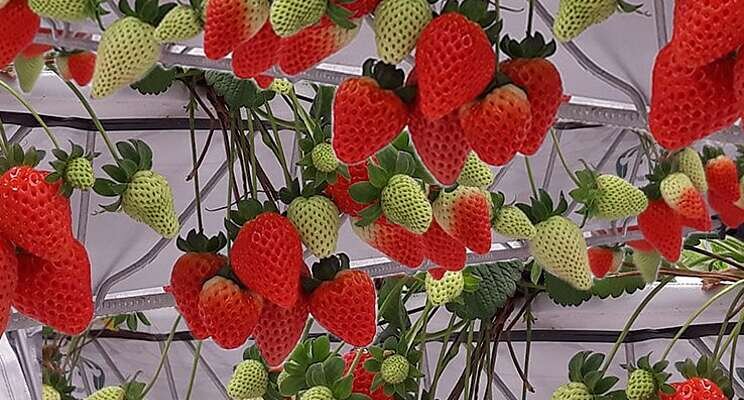

This is why Agrotonomy is now involved in promoting a state-of-the-art indoor strawberry vertical farming system manufactured in Southern Spain. This is the perfect solution for strawberry urban farming:

This indoor strawberry vertical farming system allows to grow 28 tons of strawberries in just 375m2 and/or 230 tons of strawberries in 2,500m2.

We have partnered with the world-leading hydroponic strawberry farming equipment manufacturer to promote the first-ever intensive indoor strawberry vertical farming system.

This revolutionary vertical strawberry farming system allows to grow fruits within city limits. When talking about indoor strawberry vertical farming system, we refer to 'indoors' as the inside of a building/warehouse (100% powered by artificial lights).

Due to its space efficiency, and considering its high-tech HVAC multiple climate technology, our strawberry vertical farming system is the solution to eliminate transportation and multiple intermediary handlers before the fruit reach destination.

Our urban strawberry farming system allows to farm in extreme climates 12 months out of a year. Fruits can be harvested when ripe, on a daily basis, and delivered the same day.

Although our vertical strawberry farms are 100% powered by artificial LED lights, when looking at the energy footprint, we offer a truly eco-friendly solution considering that we eliminate most of the transportation and handling processes.

To request further information, please click the following link: https://agrotonomy.com/indoor-strawberry-vertical-farms/.

Read more on Agrotonomy.

Photo Courtesy of Agrotonomy

Source: Agrotonomy

More news