Unvented heaters spell trouble

Added on 26 August 2021

An unvented heater is one that is designed without a flue connection so that the heat and products of combustion are exhausted into the greenhouse. Dumping these flue gases into the greenhouse may improve the overall efficiency rating as compared to a conventional heater, but the pollutants and added moisture from combustion may put your plants in jeopardy.

Unvented heaters can be fired with natural gas, propane or kerosene. These fuels and the heaters are advertised as clean burning. This is generally true if they are new or the burner has been recently serviced, otherwise it can emit unwanted and harmful pollutants into the greenhouse that can affect the plants and the people working with them. Let's look a little further at the fuels and the combustion process.

Natural gas (NG) consists of more than 85% methane with varying amounts of ethane, propane, butane and inert gases such as nitrogen, carbon dioxide and helium. It has a heat value of from about 950-1050 Btu/cu ft. The flue gases usually contain nitrogen dioxide, carbon dioxide, carbon monoxide, volatile organic compounds and particulate matter.

Liquefied Petroleum Gas (LP-gas) is obtained from gas wells or as a refinery by-product and consists primarily of propane with traces of proplyene, butane and butylenes. It is handled as a liquid and contains from 90,000-98,000 Btu/gal. Propane has much of the same pollutants as natural gas.

1-K kerosene is a low-sulfur petroleum product whose composition varies widely depending on what part of the world it comes from. Its heat value is about 135,000 Btu/gal. The major pollutants that result from burning kerosene are nitrogen dioxide, carbon monoxide, carbon dioxide, sulfur dioxide and formaldehyde.

The combustion process for both natural gas and LP gas are very similar. Here is the formula for burning natural gas.

1 cu ft NG + 10 cu ft Air + Flame ? 8 cu ft Nitrogen + 1 cu ft Carbon dioxide + 2 cu ft Water vapor

Non-vented gas water heaters are frequently used for root zone heat but can introduce pollutants and moisture.

Air supply

The above formula is for complete combustion. Usually, excess air is needed to get complete combustion as greater mixing occurs and more of the fuel particles will make contact with the oxygen. Incomplete combustion reduces the amount of heat that is obtained and increases the amount of pollution. A common problem in many newer greenhouses is that they are very tight. As the heater operates, oxygen is used and combustion efficiency decreases unless makeup air is available. A free air inlet of at least 1 sq in/1000 Btu/hr input is needed. Each winter there are several instances of tight greenhouses that have frozen up when the heaters were starved for air and the heat output decreased.

Carbon dioxide

One of the byproducts of combustion is carbon dioxide which can enhance plant growth. One of the problems is that carbon dioxide is most effective when light levels are the highest during the day and the carbon dioxide is mainly produced at night when the heater operates the most.

Water vapor

Another byproduct is water vapor. This is added to the greenhouse at night when moisture levels are already high and can condense out on the cold glazing surfaces and drip on the plants. Increased moisture levels can cause increased incidence of disease problems including fungi, blight and molds.

How much water do we get? Burning 1 ccf of natural gas produces about 1.25 gallons. With propane, 0.81 gal H2O per gallon burned and with kerosene 1.5 gal H2O per gallon burned. For example, if you have a 400,000 Btu/hr nonvented natural gas heater, it will produce about 5 gallons of water/hour. If the heaters were vented, the moisture would have been exhausted outside along with the flue gases. This moisture added to the normal transpiration and evaporation could keep the relative humidity well above 90%.

Other combustion products

All fuels contain traces of sulfur, some more than others depending on its source. During combustion, sulfur in the fuel is combined with oxygen to form sulfur dioxide. Levels as low as ˝ part per million (ppm) can cause injury on some plants. Once the sulfur dioxide enters the plant through the stomates, it reacts with water to produce sulfuric acid that will cause leaf burn, flecking and general chlorosis. Tomatoes and white petunias are very sensitive to this and will show signs in as little as one hour. They therefore make good indicator plants.

Ethylene gas is another pollutant formed during combustion. Levels as low as 0.01 ppm can create symptoms such as malformed leaves and flowers, stunted growth, bud abscission, epinasty and flower senescence. Levels are usually highest near the heater and can be diluted by air circulation.

Care should be taken if you install unvented heaters. Be sure to have an adequate makeup air supply and provide frequent maintenance. Use indicator plants near heaters or commercially available indicator tubes to warn of excess levels of pollutants.

John is an agricultural engineer, an emeritus extension professor at the University of Connecticut and a regular contributor to Greenhouse Management. He is an author, consultant and certified technical service provider doing greenhouse energy audits for USDA grant programs in New England. jbartok@rcn.com

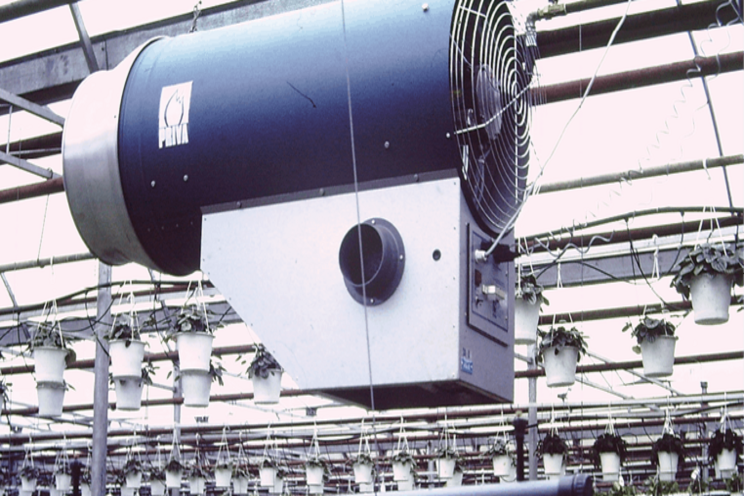

Photo: A 400,000 Btu non-vented gas heater can add the equivalent of up to 5 gallons of water as moisture to the greenhouse environment each hour.

Photos courtesy of John W. Bartok Jr.

Source: Greenhouse Management

Source: Greenhouse Management

More news