In conversation with... Ronald Hoek from Blue Radix

Added on 30 September 2024

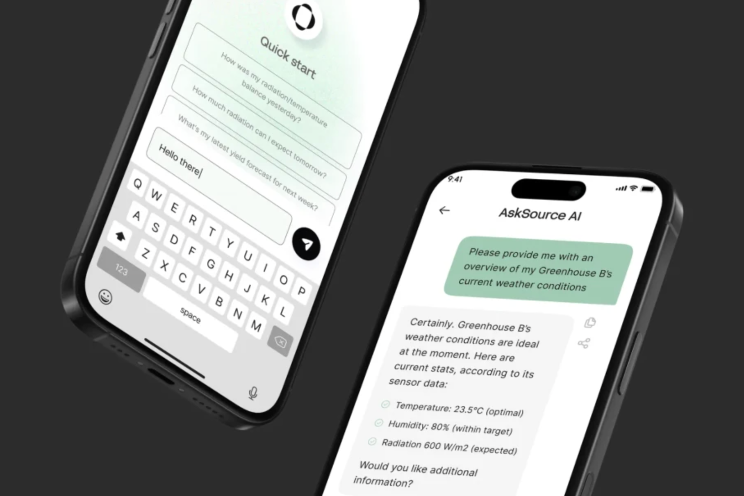

This system, an improvement of the already successful Crop Controller, enables growers to manage their greenhouses more efficiently and sustainably. In this interview, we speak with Ronald Hoek, CEO of Blue Radix , about the developments, challenges and future vision of autonomous growing.

The first question comes from Anja Dieleman (senior researcher at WUR), with whom we spoke last time: “How can the research of a company like yours support developments towards autonomous cultivation control?”

Ronald: “A fun fact is that we originate from AgroEnergy, part of Eneco, focused on greenhouse horticulture. In 2017-2018, we looked at applying algorithms in greenhouses, not only for energy, but also for cultivation. This led us to the very first Autonomous Greenhouse Challenge of Wageningen University. This was an international challenge in which teams had to demonstrate that they could achieve good cultivation results without human intervention. This initiative and the subsequent collaboration with universities such as Wageningen and TU Delft have taught us a lot about sensors, data protocols and the practical application of AI in cultivation. Although the production and research greenhouses have different speeds, the insights from the research remain of great value to us.”

Crop Controller reduces climate computer work by 80% and significantly improves profit, yield and resource use. What inspired Blue Radix to develop Crop Controller?

Ronald: “It all started with our experience in autonomous energy control. We saw the complexity of daily energy decisions for growers and knew that AI could do a lot here. With the Autonomous Greenhouse Challenge, we saw the potential to expand this technology to crop control. The big goal was to relieve growers and tackle the shortage of experienced growers.”

“Growers have to make decisions about energy, climate, irrigation and crop protection every day. This is not only time-consuming, but also stressful, because there is more and more information and data to analyze and every wrong decision can affect the yield and quality of the crops. We wanted to offer a solution that not only analyzes and presents data, but also actually makes autonomous decisions based on that data.”

“The idea was to put the grower at the center and give them the tools to gain more control and insight, without the daily administrative burden. Our ambition was and is to support growers and future-proof the sector by implementing AI-driven technologies that are both sustainable and efficient.”

What improvements do growers using Crop Controller see in their cultivation results?

Ronald: “Growers see various improvements. Such as better plant quality and higher production. By controlling the climate in the greenhouse more evenly, there is less chance of mildew and the plant grows better. This results in more production than with manual control. We have seen yields increase from 2% to 7%, depending on the circumstances. In addition, we save more energy than expected, between 13% and 18%. This is because AI can control and anticipate more accurately than humans, which leads to less energy consumption and more even plant growth.”

More news