Revolutionizing CEA with smart energy management

Added on 04 June 2024

This white paper takes you on a journey through the complex landscape of CEA energy management. It charts the path to optimizing energy consumption, reducing costs and improving the sustainability of indoor agriculture, with the smart management of Sollum®’s SUN as a Service® (SUNaaS®) cloud platform leading the revolution.

Yield and energy costs: a balancing act

The response of plants to light depends on several factors, including the crop type, variety, natural sunlight, developmental stage, and the goals of the grower.

Light is captured by photoreceptors in the leaves, and the energy is used to create carbon-based molecules, which then serve as an energy source for growth, flower, fruit development, etc. Since genetics are specific to the crop and variety, the response to environmental conditions, including light, varies between crops and varieties.

However, some responses to wavelengths (i.e., the spectrum) are generalizable and are described below. It is important to use the right spectrum to achieve the grower’s goals and maximize the profitability of the energy consumed.

In addition to the high variability of lighting strategies, with each offering a balance between energy efficiency and agronomic efficiency, multiple pricing models are offered by energy providers: time-of-use pricing, tiered pricing, dynamic pricing, and peak demand pricing.

· Time-of-use pricing structures electricity rates based on different periods, with higher rates during peak hours and lower rates during off-peak hours, encouraging consumers to shift their consumption to periods of low demand.

· Tiered pricing assigns different price levels to consumers based on their consumption, applying higher rates when consumption exceeds predefined thresholds in order to encourage conservation.

· Dynamic pricing involves real-time adjustments of electricity rates linked to market conditions, enabling consumers to react to price fluctuations and optimize their consumption.

· Finally, peak demand pricing imposes charges based on electricity consumption during a specific period, pushing consumers to manage to avoid higher charges and thus reduce overall costs.

These pricing strategies play critical roles in managing electricity demand, promoting energy efficiency, and ensuring cost-effective consumption patterns.

Given the diversity of available energy pricing models, greenhouse growers must carefully consider their choices to effectively manage energy costs. Regardless of the chosen option, it is essential that the technology used in greenhouses be appropriately adapted to optimize energy savings.

High flexibility for complex systems: an intelligent approach

In a time-of-use pricing context, the most common approach is to schedule energy-intensive activities during off-peak periods to reduce costs, and to limit consumption during peak periods. However, this ideal is often unattainable in practice, as low-rate schedules do not always coincide with the agronomic needs of crops.

The advantage of a highly adjustable power system is that during peak and intermediate consumption periods, the grower can precisely optimize the balance between yields and costs.

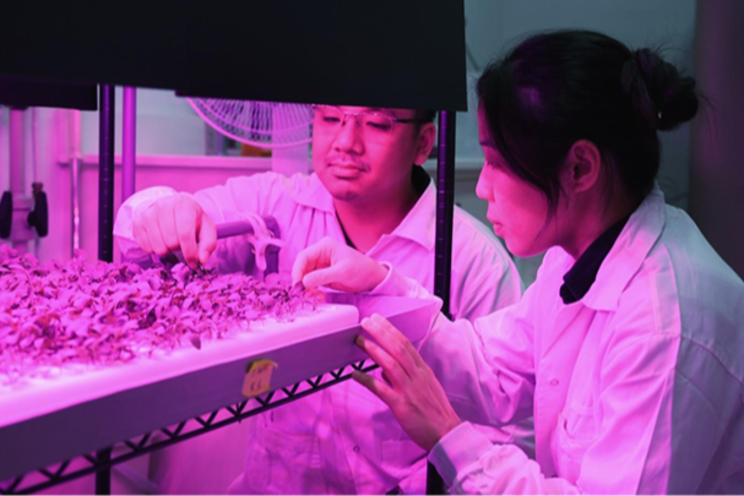

The power of Sollum's smart LED fixtures can be adjusted to fractions of a watt by changing either the light intensity (PPFD) or the spectrum. In fact, some spectrums are more energy-efficient than others, and can therefore replace more energy- intensive spectrums that are better suited to the agronomic needs of plants.

In a tiered pricing context, the ideal balance between operational costs and crop yields for each tier can be determined, and the greenhouse strategy can be dynamically adapted immediately upon reaching the next higher tier. The two methods of adjusting electricity consumption mentioned above—changing intensity and spectrum—can reduce costs when reaching a higher tier.

For example, at Hydro-Québec, the first 1,200 kilowatt-hours of the month are priced at 6.483 ¢/kWh, and subsequent kilowatt-hours are priced at 9.857 ¢/kWh.It is therefore possible to adjust equipment consumption downwards as soon as this level is reached, to avoid too significant an increase in operating costs. Close agronomic monitoring is vital for greenhouses adopting tiered billing, as different growth phases may require more energy.

For example, target accumulated light levels (i.e., target DLI) for cannabis increase dramatically over the production cycle, from 16 mol/m2/day at planting to 50 mol/m2/day at harvest. Ideally, the growing schedule should adapt to this reality by ensuring that this phase coincides with a lower tier.

In a real-time pricing environment, the use of a smart, dynamic energy management system offers significant advantages to businesses. By automatically adjusting their consumption according to current energy rates, this system enables companies to optimize their energy consumption and benefit from lower rates.

This real-time reactivity enables significant long-term cost savings by shifting part of energy consumption to more favorable price periods. What's more, automation simplifies the cost-based adjustment of intensity and spectrum, reducing the need for manual intervention and freeing up resources to improve operational efficiency and sustainability.

In the context of power demand, an ideal system must have two key features to optimize power consumption. The first is to estimate the ideal peak consumption that balances output and operating costs for the billing period. This peak can be calculated using historical data and weather forecasts.

The second feature is the system's ability to limit maximum equipment output so that it never exceeds the optimal limit determined by the system. For example, several crops are transplanted into the greenhouse at the beginning of September, when there is still plenty of natural light and the needs of young plants are lower. By reducing the maximum power of the fixtures at this stage (e.g., limiting the maximum power to 75%), the grower reduces his maximum demand and therefore power demand costs.

The more precisely that maximum power is controlled, the more growers can optimize their energy use and profitability of the company. As an example, Hydro-Québec calculates the power to be billed by taking 65% of the highest peak demand during the months of December, January, February and March of the previous year. Reducing the maximum power used during these four months can therefore substantially impact the annual energy bill.

A real problem gets a real solution

To understand how a smart system can make decisions based on the needs of the plant and the greenhouse grower, here's a real-life situation.

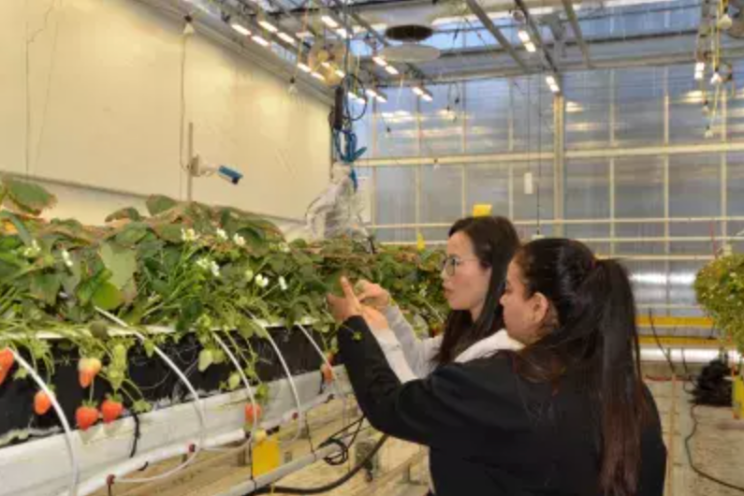

Consider a strawberry grower with a neutral day who has just planted. The strawberry plants are in their vegetative growth phase, during which the main goal is to encourage leaf growth and produce an open canopy that allows good air circulation.

At this stage, a light recipe with a higher far-red output is recommended since this wavelength stimulates stem elongation and leaf expansion.

A grower could therefore start with the following set-up:

Optimum spectrum: high far-red content

Optimum intensity: 220 μmol

Spectrum efficiency: 3.05 μmol/J

Photoperiod: 16 hours

The energy utility tells us that 3 hours of our planned photoperiod will be considered peak time, increasing the rate by 10%. The system offers several options.

Option 1 : change intensity during peak periods

The system can reduce the intensity to 200 μmol to consume 10% less electricity.

Option 2: change spectrum during peak periods

The system can change the spectrum during peak periods to use only the most efficient channels, improving spectrum efficiency from 3.05 μmol/J to 3.36 μmol/J, thus reducing power consumption by 10%.

Option 3: shifting the photoperiod

The third option is to turn off the fixtures during the peak period and extend the photoperiod by 3 hours.

In this kind of situation, the system’s decision-making algorithm needs to be adapted to the agronomic needs of the crop. In this case, research indicates that a 16-hour photoperiod is optimal for strawberries, and that the minimum intensity should be 150 μmol to ensure effective photosynthesis. Modifying the spectrum, intensity or photoperiod during peak hours is a temporary measure aimed at reducing energy costs with minimal impact on the crop. Once the peak hours are over, the system reinstates the optimized settings for growth.

Conclusion: illuminating the way forward

The intersection of technology, agronomy and intelligent energy management holds the key to unlocking the full potential of CEA. Sollum is at the forefront of a more sustainable, efficient and productive future for greenhouses.

Sollum's mission goes beyond solving today's challenges; they are committed to preserving the ecosystem by offering a sustainable solution that contributes to quality of life and supports local economies. With innovative strategies, real-time data analytics and a deep commitment to sustainability, Sollum is ideally positioned to revolutionize modern agriculture.

To find out how we can light the way to a greener future, visit Sollum's website.

More news